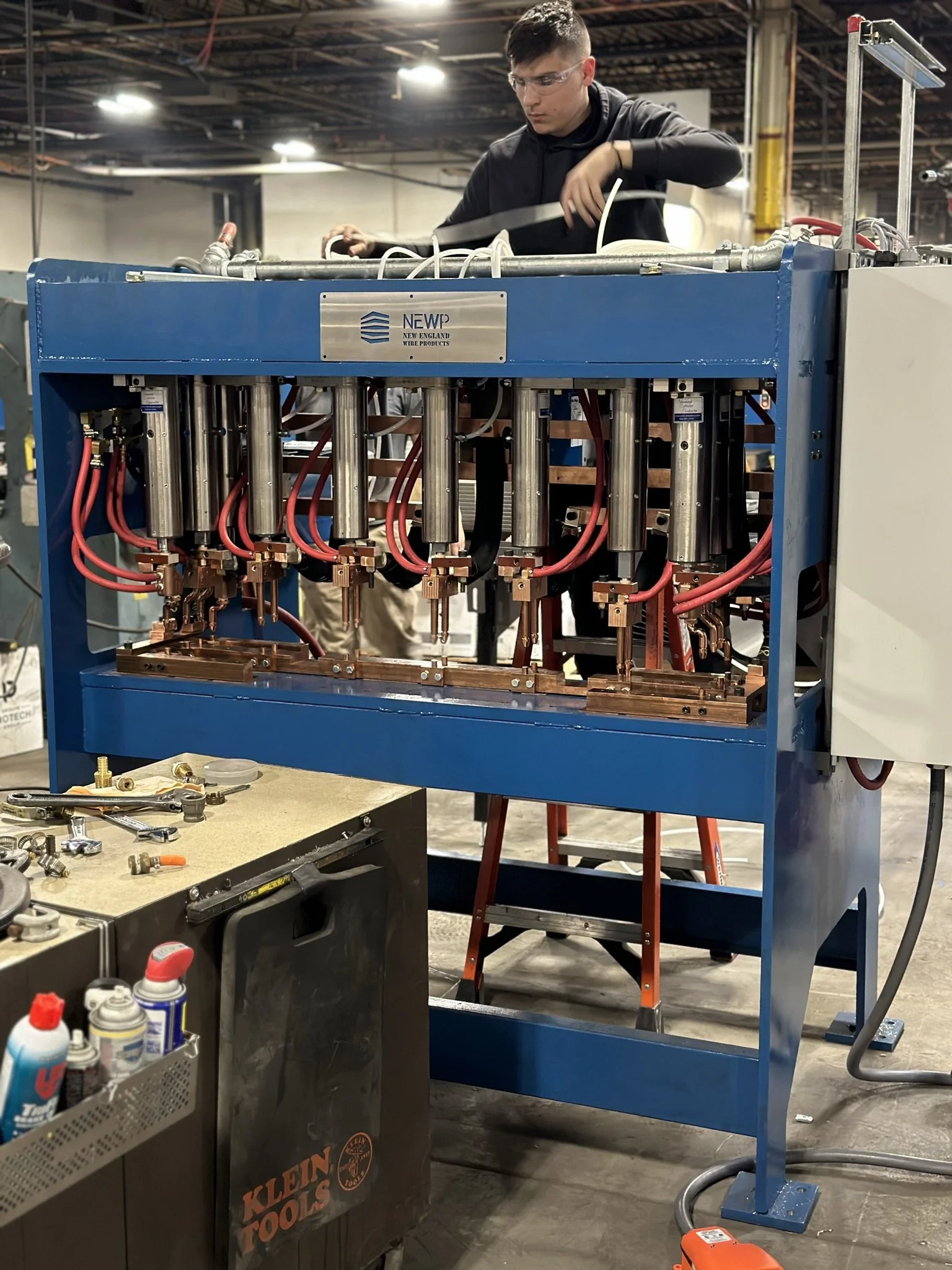

Multi-head Spot Welder

Manufacturing initiative to improve process capability.

Key Attributes

11 cylinder design combines two lengthy spot welding processes into a single short one.

Final MIG welding step integrated into work cell to minimize WIP/eliminate waste.

Customized fixturing allowed for easy loading and precise, repeatable welds.

Timeline/Budget: $70,000; 3 months

Highlighted Problem and Solution

Loss of current in the middle welds which resulted to poor joints; attributed to induction losses.

Switched to push/pull wiring to minimize surface area of electrical loop.